Hamachirimen

White fabric with a beautiful grain created

by Hatcho twisted yarns

Hamachirimen

Hamachirimen

Hamachirimen

of

history

Hama Chirimen,

which evolved uniquely on the beaches of Lake Biwa

It is said that ”Hama Chirimen” was introduced to Japan between 1720 and 1750 from Nishijin or Tanbo, but it is not known for sure.

The production of chirimen weaving is said to have originated from Tango.

Chirimen weaving production spread from the area around Ogo Village to the entire Nagahama area, and eventually came to be sold in Kyoto and Osaka via Lake Biwa.

Eventually, it came to be sold in the Kyoto and Osaka areas, and crape weaving came to be called Hamachirimen (Nagahamachirimen) because it is Nagahama’s ”Chirimen,” but Kyoto businesses began to view Hamachirimen as dangerous and confrontational, saying that it was interfering with their business.

In order to solve this problem, the Hikone Clan entered into an intermediary relationship with Kyoto, and began to have Hamachirimen paid as annual tribute and sold on its behalf.

The Hikone Clan praised the achievements of Nakamura Rinsuke and Inui Shokuro, who worked hard to solve this problem on site, and ordered them to become weavers of Hamachirimen, giving them the privilege of inspecting their products and collecting inspection fees.

As a result, the poor quality products that did not have the weaver’s seal could not be sold, and the Hikone Clan protected Hamachirimen, and as a result, the production area developed as an important specialty product. Hamachirimen is now known as "Hama Chirimen" and is known throughout the country as the best white fabric.

The best white fabric with beautiful grain

by Hatcho twisted yarn

Hama-Chirimen is a silk fabric with beautiful shibo (graininess) made of Hatcho-Twisted Yarn.

The manufacturing process is one of the characteristics of Hama Chirimen, and all the processes from raw silk to woven fabric, except for scouring, are done by the company’s own integrated production process.

In order to produce the ideal texture and grain, the weft yarn is twisted a number of times and the manufacturing process is carefully controlled to produce the best white fabric.

Another feature is that water from Lake Biwa, which is soft, is used for scouring, and water from the melting snow of Mt.

PROCESS

canonization

canonization

In the Nagahama silk production area, a method called partial warping is used, in which a specified number of threads are wound from about 500 bobbins onto a winding core called a beam to a specified width and length according to a standard. There are many types of Hama Chirimen, but the standard warp is approximately 9,000 threads, 41 cm wide and 16.5 m long, and the warp is wound in batches of 30 to 50 warps in the warping process.

weaving in

the wrong order

weaving in the wrong order

The greatest feature of Hama-chirimen is the richness of expression created by the unevenness of the fabric’s surface, called shibo.

The shibo is mainly produced from a weft called hatcho nenshi.

Weft boiling is a preparatory process for Hatcho twisted yarns, in which raw yarns are boiled in hot water at 98°C for about 30 minutes (depending on the variety).

The surface of the raw yarn contains a protein called sericin.

When the yarns are boiled, sericin becomes like glue, and the aligned yarns stick together so that they do not fall apart.

The yarn itself also becomes soft and supple, making it easy to apply strong twisting.

The greatest feature of Hama-chirimen is the richness of expression created by the unevenness of the fabric’s surface, called shibo.

The shibo is mainly produced from a weft called hatcho nenshi.

Weft boiling is a preparatory process for Hatcho twisted yarns, in which raw yarns are boiled in hot water at 98°C for about 30 minutes (depending on the variety).

The surface of the raw yarn contains a protein called sericin.

When the yarns are boiled, sericin becomes like glue, and the aligned yarns stick together so that they do not fall apart.

The yarn itself also becomes soft and supple, making it easy to apply strong twisting.

twining of thread or yarn

twining of thread or yarn

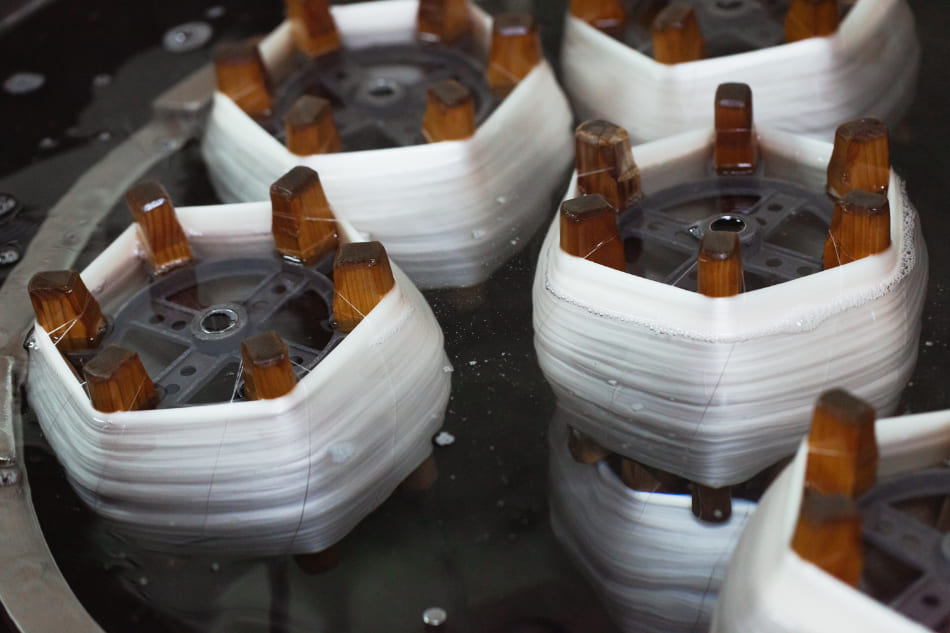

In the Hatcho twisting process, strong twisting is applied to the raw silk while water is applied to prevent the sericin from drying out.

This process is the heart of Hama Chirimen, which determines the texture and hand of the white fabric, and is filled with know-how inherited from our predecessors.

In the Hatcho twisting process, the yarn is twisted approximately 2,000 to 4,000 times per meter. After twisting, the yarn is slowly dried over a number of days.

At this time, sericin sets the yarn so that the twists applied to the yarn do not return.

Groundwater is used, because the warm water of the groundwater is constant throughout the year at about 16°C, which stabilizes the quality of Hatcho twisted yarns.

In the Hatcho twisting process, strong twisting is applied to the raw silk while water is applied to prevent the sericin from drying out.

This process is the heart of Hama Chirimen, which determines the texture and hand of the white fabric, and is filled with know-how inherited from our predecessors.

In the Hatcho twisting process, the yarn is twisted approximately 2,000 to 4,000 times per meter. After twisting, the yarn is slowly dried over a number of days.

At this time, sericin sets the yarn so that the twists applied to the yarn do not return.

Groundwater is used, because the warm water of the groundwater is constant throughout the year at about 16°C, which stabilizes the quality of Hatcho twisted yarns.

Italian twisted thread

Italian twisted thread

The italy twist yarn process can produce yarns with a number of twists ranging from 100 to 2,500 times per meter. Unlike haccho twisted yarn, this process is sometimes called dry twisting because the yarn is twisted while it is dry. For "Modified Chirimen" with little shrinkage, a combination of Hatcho twisted yarn and wall yarn* made using an Italian twisted yarn machine is used.

Gonyu is the last process of producing weft yarns for Henri Chirimen, in which Hatcho twisted yarns and wall yarns are twisted together. The shape of the yarn is determined in the Gonyu process, and it is an important process that determines the shape and size of the shibo on the white fabric.

twisting

twisting

What is wall thread?

Kabeyon is a twisted yarn that helps reduce shrinkage and increase the firmness of Hama-Chirimen. Kabeyon is made by twisting three or four raw yarns twisted 2,000 times per meter using Italian twisted yarn, and then twisting one more raw yarn together.

weaving

weaving

Weaving is the process of weaving the warp and weft into a standardized fabric. All the processes of Hama Chirimen are important, but if weaving is not done properly, all the 30 to 40 processes up to that point will be ruined, so great care and skill are required. In addition, maintenance and adjustment of the weaving machines are also essential.