Hamatsumugi and Amioritsumugi

Fabric with a unique texture favored

by kimono lovers

Hamatsumugi

Hamatsumugi

Widely accepted Hama no Tsumugi

In the Nagahama silk production area, Maru-ori tsumugi, a weft yarn woven with hand-spun leftover crape yarn wrapped around the raw silk warp, which is the same unrefined silk yarn as crape, has been woven since the end of the Meiji period. Various innovations led to the weaving of many types of tsumugi, and in the early Showa period (1926-1989), a new type of tsumugi, Hama tsumugi, was developed. At present, Hama-sumugi is woven using wild silkworms and machine-made cotton.

History of Hamatsumugi

Various customized fabrics

by artisans

Hama tsumugi is mostly made by weaving non-twisted raw silk threads as warp and variously devised tsumugi yarns as weft, similar to chirimen. The original of this type was Maru-tsumugi, which was made by weaving hand-spun threads made from leftover threads of Chirimen. Later, various types of weft were produced, and a wide variety of tsumugi silk was woven, including machine-made cotton and wild silkworm yarn. Some warp yarns have knots in them, and some are woven with pre-kneaded yarns that are refined at the thread stage for both warp and weft, giving them a different texture from Hama silk, the original Maru silk.

PROCESS

pasting

pasting

In order to make weaving easier, Hama silk is coated with glue on the warp and weft yarns. The viscosity of the glue, which is made from natural starch paste, is carefully adjusted in consideration of the finish and texture of the fabric. The fabric is allowed to dry naturally to avoid static electricity caused by friction, but it takes two to three days in summer to dry completely.

In order to make weaving easier, Hama silk is coated with glue on the warp and weft yarns. The viscosity of the glue, which is made from natural starch paste, is carefully adjusted in consideration of the finish and texture of the fabric. The fabric is allowed to dry naturally to avoid static electricity caused by friction, but it takes two to three days in summer to dry completely.

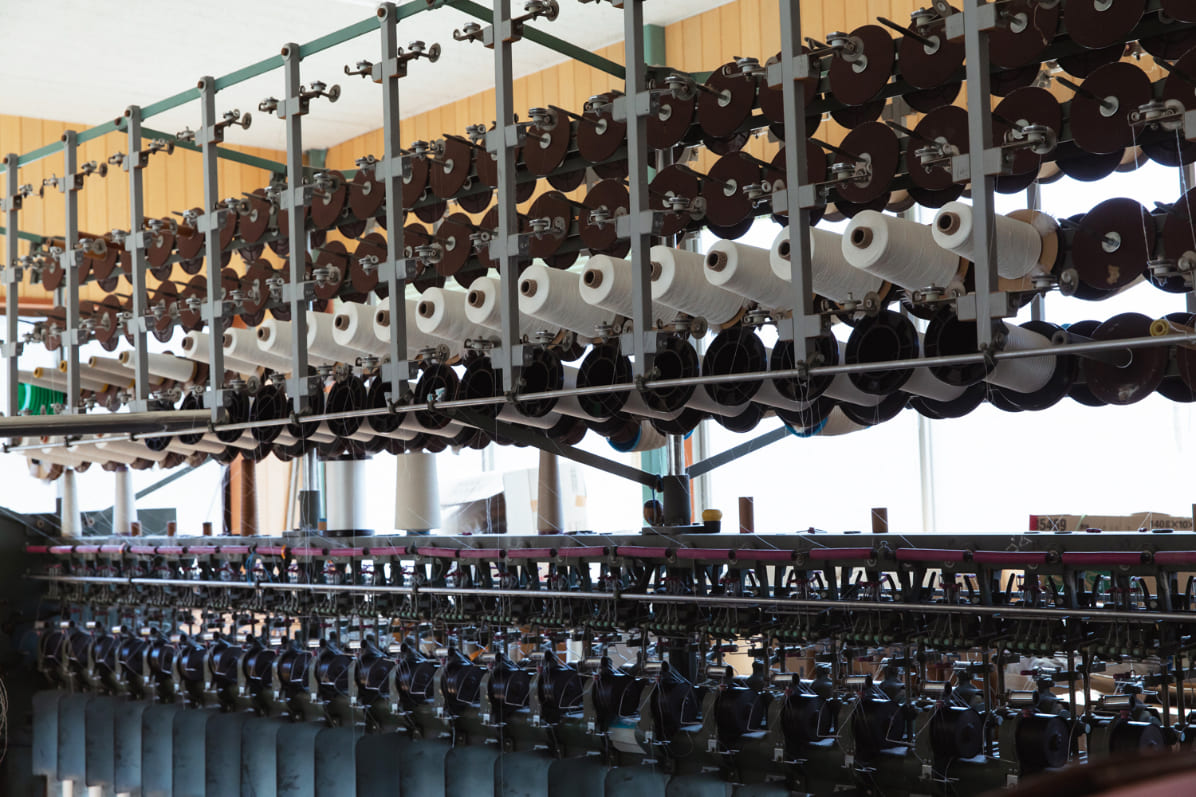

twisting

twisting

Unlike Hama Chirimen, weft yarn is made by twisting multiple yarns together at a rate of about 300-500 revolutions per meter using a twisting machine instead of a Hatcho twisting machine.

Unlike Hama Chirimen, weft yarn is made by twisting multiple yarns together at a rate of about 300-500 revolutions per meter using a twisting machine instead of a Hatcho twisting machine.

weaving

weaving

Hama-tsumugi is often made by aligning untwisted raw threads in the warp, which is similar to the warp production process of Hama-chirimen (warping). Basically, the same looms are used for Hama Chirimen, but dobby looms that can weave other fabrics than plain weave are sometimes used.

Hama-tsumugi is often made by aligning untwisted raw threads in the warp, which is similar to the warp production process of Hama-chirimen (warping). Basically, the same looms are used for Hama Chirimen, but dobby looms that can weave other fabrics than plain weave are sometimes used.

Amiori tsumugi

Amioritsumugi

Amiori tsumugi

of

history

Amiori tsumugi made from fishing nets

In the mid-Edo period, sericulture was thriving in Nagahama, and silk fishing nets were used in Lake Biwa, giving rise to Amiori tsumugi made by weaving used nets into yarn.

Raw silk yarn from inside and outside of Japan is used for the warp, and silk yarn made from fishing nets is used for the weft.

The process of bringing the whiskers of the fishing nets to the surface requires great skill and has been designated as a traditional craft of Shiga Prefecture.

Unique texture with

whiskers popping out

Amenori silk is the most austere and deeply textured of all woven fabrics, and is favored by kimono lovers. The whisker-like cut surface of the net when it is cut gives the fabric a unique texture. There are many variations of Amiori tsumugi, such as those with Zenmai (cotton threads mixed with cotton threads from wild plants) or Kenneri Tamayo (threads made from two silkworms in one cocoon), and its unique texture is favored by men and women alike.

PROCESS

thread dyeing

thread dyeing

thread dyeing

thread dyeing

The netting used for Amiori silk is first dyed by repeatedly soaking the netting three to ten times in a liquid extracted from astringent persimmon fruit or silk dye solution.

This process originated from the fact that fishermen used to apply persimmon tannin to their nets to give them a preservative and insect repellent effect.

One cut netting thread is connected and rolled up into a frame.

thread grafting

thread grafting

Align and tie the nodes of the netting and cut every 2 or 3 nodes.

half-tone

half-tone

Align and tie the nodes of the netting and cut every 2 or 3 nodes.

covering

Covering is a process mainly performed on the weft of women’s kimono. Since most women’s kimonos are dyed with patterns instead of plain colors, the unique whiskers of amiori tsumugi sometimes get in the way during dyeing. In order to make the threads flat without making them fluffier, a process called covering is applied to suppress the whiskers by wrapping the raw threads around the top.

covering